Hacks for Tension

equipment hacksSooner or later it will happen that you have a thread or two that's too loose. And eventually you may have a warp where it's quite a lot of threads! Here's some ideas for ways to deal with the problem.

My latest warp is my first where I've had more than a couple problematic threads - I think one issue is the two different kinds of warp threads, as most of the tension issues are with the red rayon chenille rather than the black Tencel. Probably there's also room for improvement in my warping and tying on!

When I've had a couple threads that are a bit loose, one thing that works is just to shove a little scrap of cardboard, paper towel, etc. to help those threads stay tighter. This is the only thing I've needed for my previous projects. One thing I tried that didn't work was allen keys that were L shaped or kind of S-shaped but with 90 degree corners - you really need more of a curve to get it to stay in.

The other way to deal with tension is to add some weight to loose threads. My first improvisation here was to think of what I had with hooks on it - and remembered we had a pack of bungee cords. The bigger ones in the photo have a cap on the end that tends to make them a little harder to get out if the threads start to twist, which often happens when you advance. I'm not recommending going out and buying bungee cords for this purpose, just that it was something I had on hand that did the job that might inspire you to think of something that you've got! Another thing that I think could work that I haven't tried is using some scrap yarn to tie a weight on - perhaps some washers on a length of string, or an old pill bottle with some pennies or screws inside for weight.

As I've gone through this warp more and more threads have been needing help, and I was running out of the smaller bungee cords and it was getting unwieldly with so many bungee cords. So I went out and got some S hooks, which I'd seen recommended. I ended up picking up a package of 30 5/32" and a package of 20 3/16" as I knew I needed a bunch and I wasn't sure what size would be best. Each package was less than $10. The ones I got are designed for connecting lengths of chain and were with the chain parts in a hardware store. Both sizes work - the smaller ones are good for the threads that are just a bit loose and the bigger ones for ones that need more help. At this point I'm nearing the end of my warp and most of the red threads have something dangling off them; I have so many S-Hooks my loom is now a musical instrument!. It's actually a fairly pleasant wind chime type noise as I weave. I haven't felt the need to do this but I could add some washers or bolts to adjust the weight a bit.

All of these approaches need more fussing around to move your weights or scraps back into place after advancing the warp; it's not ideal to get tension issues but it's probably going to happen sometimes! Hopefully your warp doesn't get as bad as mine, I'm liking the fabric that's coming out of it but tension has been a big issue! Good thing I don't have too much more to weave on this warp!

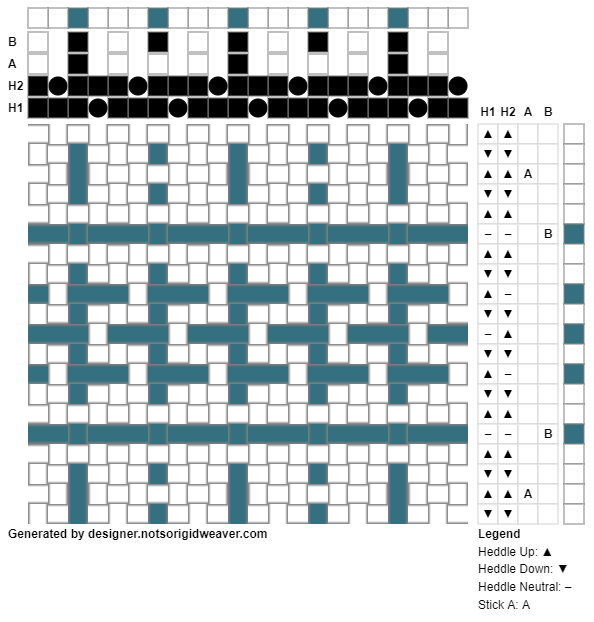

Check out Not So Rigid Designer, the online weaving software for rigid heddle loom weavers!