What is a rigid heddle loom?

getting startedterminologyloomThe very short version is a rigid heddle loom is a loom that uses a rigid heddle to weave by moving the heddle up and down to create a space (the shed) to pass a shuttle through.

That’s great, but what is a rigid heddle? A rigid heddle is a solid piece with holes and slots that can be moved up and down to produce a shed. The holes and slots are fully enclosed and not simply notches or hooks. When the heddle is moved up and down, the hole yarns move up and down while the slot yarns stay in one plane. I have a whole post discussing it in comparison to some related pieces of shaft looms if you want more detail.

My basic requirements for a rigid heddle loom are:

- It is designed to produce a shed with a single rigid heddle, with a concept of up, down, and neutral positions.

- The loom holds the tension and has a mechanism to roll up cloth and warp to produce a fabric longer than the frame of the loom.

- The rigid heddle is not attached to the loom, except via the warp.

Additionally, the following features are present in most modern rigid heddle looms by the main manufacturers and make for a better weaving experience:

- Multiple sizes of heddles are available to work with different thicknesses of yarn.

- Has a way to support the rigid heddle in the up, down, and neutral positions; and often has supports for 2 and sometimes 3 heddles.

- Provides a secure mechanism like a ratchet and pawl to advance the warp and maintain tension (designs like wing nuts, a rotating bar, or clamps are more fiddly).

- The rigid heddle is designed to be used as a beater (some older designs using wire are a bit more fragile).

- The holes are oval and not a tiny circle so that they allow using a larger hook to thread.

- The heddle is big enough to make a good shed - tiny heddles produce tiny sheds. The visible plastic on my Ashford heddles is a bit over 3”, the entire piece with the wood is well over 4” tall, while the heddle on the toy loom I describe below was probably less than 2".

- Uses an apron rod to attach the warp.

- Can handle a warp that's a few yards long, e.g. to make an adult sized scarf, 4-6 placemats, etc.

The rigid heddle looms by Ashford, Glimakra, Schacht, Leclerc, and Kromski meet all of those requirements. The larger Beka looms don’t use an apron rod, while their 4 and 10” Beginner’s Loom models are missing most of the quality of life features to keep costs low.

The photo above has an example of a simple toy loom on the left, a Spears loom from the 1980s. It meets the basic definition, but has none of the quality of life features, and it's really only suitable for very small projects. The heddle is tiny, and was difficult to use without getting fingers in the way, causing floats, and while the warp can be rolled up a little - the pieces that hold the warp and the fabric lift out and can be turned, but it's hard to maintain tension while doing so and some of the yarns would fall out of the teeth that hold them in place. I was able to play around with a pick up pattern though - it functions as a rigid heddle loom, just not very well.

On the right, I've got my 16" Ashford Sample-It (with a narrow band on) sitting inside my 24" Ashford Rigid heddle loom. There are heddle blocks on the sides, a ratchet and pawl system to advance the warp, and the warp is attached with an apron rod.

What are some advantages of this design? #

Rigid heddle looms are lightweight and inexpensive compared to shaft looms and offer a wide range of patterning capabilities through using pick up sticks or multiple heddles. They are simple to learn to weave on, but can also offer a great deal of flexibility with a bit more effort. You can use them to weave moderately long, moderately wide fabric.

The magic of a rigid heddle loom for patterning is that the slot yarns can be freely manipulated to enhance the patterning capabilities beyond plain weave. Importantly, you can insert a pick up stick and leave it in place; pick up patterning can be done on most looms, but usually the stick can’t be left in place and saved. But you can also change the pick up pattern easily at different places in your warp, which can lend itself to some kinds of designs that are impractical on shaft looms, or at least on the 4-8 shafts most weavers have!

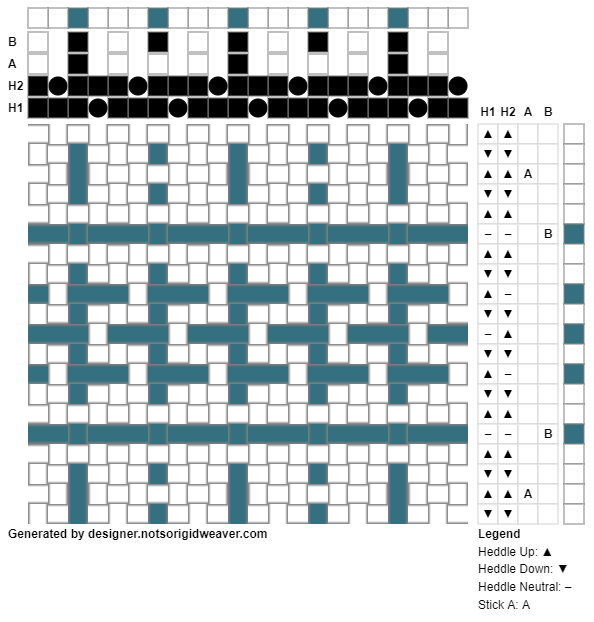

You can also use 2-3 heddles in sequence to produce patterns you would need 3-4 shafts for, or beyond when combined with the flexibility of pick up. When doing even more intricate designs that use multiple pick up patterns in sequence, you can also use string heddles on a heddle rod to save more than one pattern.

And some disadvantages? #

While rigid heddle looms are very flexible tools, they are slower to weave on than a shaft loom, particularly when doing more intricate patterns that work well with the constraints of a shaft loom. Rigid heddle looms are also not very good at dealing with fine fabric.

Because the weaver needs to manipulate the entire heddle, many people find narrower rigid heddle looms much easier to work with; they are available in widths up to 48”, though most manufacturers only go up to 30-32”, and many people prefer to stick to 24” or narrower.

All told, rigid heddle looms are a great place to start with weaving, or, a great place to move up to from an even simpler loom!

Check out Not So Rigid Designer, the online weaving software for rigid heddle loom weavers!