About the Ashenhurst Sett Calculator

planning projectsOne important consideration when planning a weaving project is the sett - the spacing of the warp threads. As rigid heddle weavers, this is influenced by the heddles available, and there is less ability to fine tune the sett than on a shaft loom, but there still are a range of choices which may produce a reasonable fabric with a given yarn. One common approach is to calculate the wraps per inch, and divide it by half, as the starting point for balanced plain weave. This works fairly well for thick yarns, but as yarns get thinner it can be tedious. Another approach is to consult a sett chart (such as Handwoven’s Master Sett Chart), or the advice of the yarn seller, but these may not always include the yarn you have, and sometimes advice is contradictory.

A third approach is to calculate it based on the weight of the yarn. Ashenhurst’s rule is a way of calculating a sett for yarn based on the yards per pound and (optionally) the type of fiber, and then the weave structure and intended use of the fabric. It’s an alternative to using wraps per inch, and is used by Peggy Osterkamp in her books and sett charts. It is particularly suited for thinner yarns where wraps per inch would be higher and fairly tedious to calculate. I have created a calculator, which is on it’s own page here, and embedded below. Enter in the length (in yards or meters), and the weight (in pounds, ounces, or grams), and optionally the fibre type, and the calculator will output the yards per pound, Ashenhurst diameters per inch, and a range of suitable setts for different weave structures and fabric types.

The setts are based on weave structure and the purpose of the fabric. For weave structure, values are currently included for plain weave and twill, and are based on how many warp and weft interlacements there are in a row of weaving - plain weave is 1/2 and a 4 shaft twill is 4/6. For fabric purpose, 90% of the maximum is suggested for upholstery fabric that isn’t intended to shrink much when finished, 80% is a fairly typical value; it will produce a slightly warp dominant weave but this is very common. For woolen fabric that will be loosely woven but is expected to shrink significantly during wet finishing, 65% of maximum is suggested. Clothing is typically 60-70%, while delicate fabrics like a shawl or curtain can be 50-60% of the maximum. On a rigid heddle loom, you have fewer options to manipulate sett than on a shaft loom, but these values give better guidance about a range of reasonable options than sources that simply give one or a couple exact numbers.

The twill setts are also suitable for basketweave (e.g. doubling yarns in a rigid heddle). A 3 shaft twill has fewer interlacements than a 4 shaft twill (3/5 instead of 4/6), and so would be in between the plain weave and twill values. Pick up patterns are mostly plain weave, however, do have fewer interlacements in many rows - you might choose to go a little higher for them than a pure plain weave.

For example, the numbers would suggest that for 8/4 cotton, you could reasonably use a 10, 12, 12.5, or 15 DPI heddle for plain weave, or doubled in a 7.5, 8, or 10 for a basketweave or twill structure.

Finally, these are all for a balanced weave structure. Decrease the sett for a weft dominant weave and increase it for a warp dominant weave.

For more detail on these calculations, check out Peggy Osterkamp’s blog, and chapter 13 of her book, Winding a Warp & Using a Paddle.

Like any method of calculating sett, these numbers are a starting point. I have found that for thicker yarns like worsted cotton, it might suggest a little high - so far as I understand the formula was devised around industrial weaving yarns in the late 19th or early 20th century which would be much thinner. Sampling is always the safest way to ensure you get the fabric you’re looking for!

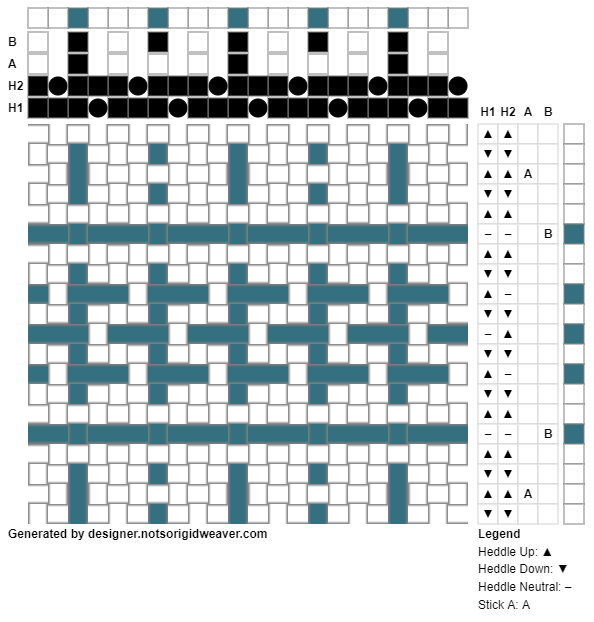

Check out Not So Rigid Designer, the online weaving software for rigid heddle loom weavers!